The Scent of Beitou’s Elements

Text - Yu Ju-Ling(游如伶)

Photography - Tsai Yao-Cheng(蔡耀徵)

Illustrations - Chen Wan-Yun(陳宛昀)

The Artisan Mind of Hotspring Flower’s Founder Mao Hsien-Ning

Photo: Mao Hsien-Ning, founder of Hotspring Flower.

“Tanghua” (湯花), literally translated as “hot spring flower” is a substance formed by the natural sediment process that occurs in hot springs. It is named due to its resemblance to snowflakes in the hot springs. Once the sediment becomes deposited at the bottom of hot springs, it can be treated to create hot spring powder. By adding hot water to dissolve the powder, it is possible to recreate qualities similar to hot springs, which allows people to enjoy the healing nature of hot springs from the comfort of their homes.

Mao Hsien-Ning, founder of “Hotspring Flower” has a mother from Beitou. He remembers that every time he went back to his mother’s house on Gongguan Road, there would always be a strong or weak smell of sulfur. He also recalls boiling eggs in Beitou Geothermal Valley during his childhood. Tor him, the promotion of the hot spring flower industry is something he holds dearly due to his family geographical connections that he possesses.

Photo:Hot spring flower crystals.

10 grams of hot spring powder will allow one to recreate the healing feeling of hot springs with a half-filled domestic-sized bathtub.

Precious Hot Spring Flowers, Example of a Circular Economy

“Waste is just something we have not found a method to use. Tanghua is a perfect example of a circular economy and sustainable business model.” Mao Hsien-Ning began working with the Taipei City Government in 2011 to produce limited quantities of products based on industry-academia collaborative research of Beitou hot spring flowers. He has since been advising hot spring owners in Beitou in the production and sales of hot spring flowers.

When the hot spring water flows into the pipes of the hotel, it will accumulate in the “hot spring tank” to be stored. Originally, this needed to be dredged and cleaned every year, but after recycling, it can be made into hot springs powder and for use in a variety of products such as handmade soaps and skin care products, etc. Making these products under the idea of “hot spring to go”, this creates additional value for the traditional hot spring industry. In order to promote the hot spring flower products made by the hot spring industry, Mao Hsien-Ning even established the “Hotspring Flower” shop in 2016 as a location specializing in the sale of hot spring flower products.

As one of the first individuals to invest in the research and development of the Beitou hot spring flower industry, Mao Hsien-Ning has experience in every part of the supply chain, including production, advising, establishing product certification systems, formulating marketing strategies, building brands and operating stores. Being in charge of so many things at once meant that he was often busy to the point of exhaustion. He decided to return to the source of the product after careful consideration. After its transformation, his Hotspring Flower brand decided to focus on R&D and production, with the “Hot Spring Store” operated by Lan Chih-Ling (藍智玲) in Beitou, by using its store front as the main point of distribution, furthering the brand’s local connection.

Photo: Thermal Valley Workshop is one of the vending locations for the HotSpring Flower brand.

Investing the Artisan Spirit into the Collection and Production of Hot Spring Flowers

Having traveled to various hot spring areas in Japan to research and learn about their hot spring flower production, Mao Hsien-Ning has been able to gain in depth knowledge on the industry. For example, the “Kusatsu Hot Springs” has a relatively substantial flow. Thus, laying a wooden gutter for the springs in “Yubatake” was the approach taken. When the hot springs flow through, the water is deposited and circulated continuously in the gutter. For “Myoban Hot Springs”, since the amount of water is smaller, laying stones where the sulfur gas is emitted, and then covering it with a layer of green clay like a Petri dish, would allow the crystals of the springs will multiply and adhere to the surface of the clay. These different approaches allow for the regular collection of the crystals. These techniques of collection dating back to the Edo Period have been designated as an Intangible Cultural Property by the Japanese government.

Since the creation of hot spring flowers is an ancient craft, Mao Hsien-Ning's role is more akin to that of a craftsman or artisan. “For every ton of hot spring water, only one gram of hot spring powder can be produced. Combined with a collection process that is both difficult and complicated, this is an example of the preciousness of Tanghua.”

As the source of Beitou’s hot springs are almost all within the Yangmingshan National Park, relevant restrictions for conservation purposes make navigating the production also difficult. Therefore, Mao Hsien-Ning mainly cooperates with hot spring owners to obtain raw materials from the hot spring tanks in hotels. He also pointed out associated dangers of collecting from hot springs: “Some old hot spring hotels have tanks located on the underground floors which are often non-ventilated environments. This means that they are prone to producing toxic hydrogen sulfide gas. If the quality of the hot springs cannot be guaranteed and there are safety concerns, I will choose to forgo cooperating with them.”

In addition, the collection period is mostly in the off-season of the hot spring industry, which is the summer. Since it is necessary to wear protective equipment, he often sweats profusely while digging shovel by shovel. An extremely tedious process indeed. A hotel owner once described Mao Hsien-Ning as “an honest man without a profit centric way of thinking”. This sentence also shows his gung-ho attitude towards working hard in the hot spring flower industry.

Photo: Sulfur Valley in Yangmingshan National Park is one of the sources of Beitou hot springs and hot spring flowers.

Taking Home the Hospitality of the People of Beitou

Though the hot spring flower industry seems to be a new and local innovation, the manufacturing technology used and the development of Beitou’s hot spring flower dates back to the sulfur mining business and hot spring tourism in Yangmingshan area during the Japanese era. There were already sulfur mine owners that were producing and selling hot spring flowers to Taiwan and Mainland Japan under the name “Seven-Star Hot Spring Flowers” at the time. After the war, the hot spring flower industry in Beitou slowly fell silent, and it did not develop again until roughly a decade ago.

When beginning to promote Tanghua, most of the people Mao Hsien-Ning came into contact with had never heard of it. He decided to go to the Beitou farmer’s market every month to display and sell his products, hoping that more people could know about this local specialty. Over the years, Beitou Tanghua have become a representative souvenir for visitors to take home. Cooperating with different entities for products have also taken place. For example, his HotSpring Flower Shop and the Beitou Hot Spring Museum have launched a handmade soap that was a collaboration project; When the nearby National Yang Ming Chiao Tung University merged, the HotSpring Flower Soap was chosen as a gift for alumni. “At that time, the two schools each chose well-known items in close proximity as representative gifts, and Yang-Ming University located in Beitou chose the HotSpring Flower Soap, which means that Tanghua has been recognized locally.” Nowadays, in addition to coming to the hot spring town to be healed by the elements, tourists can also bring home the hospitality of the people of Beitou. As Mao Hsien-Ning said, “Tanghua, which connects the body, memory and nostalgia, is also the most representative of Beitou due to many people remembering the smell.”

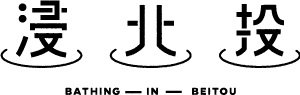

The Production Process of “Beitou Hotspring Powder”

1. Gather raw materials: Raw materials are gathered for the Tanghua in the “hot spring generation facility” in the hot spring area or the “hot spring tanks” in the various hot spring hotels. During collection, the hot spring water in the tanks must be drained, and the sediment should be excavated with a shovel before being placed into a rice bag.

2. Dehydration and drying: As the raw materials of hot spring flowers have high water content, they can be placed into a rice bag to dry naturally. To ensure complete dehydration, the materials can be placed into an induction cooker or dryer, which can also be used for ultraviolet sterilization.

3. Removal of impurities: The dehydrated and dried hot spring flower raw materials usually contained mixed with leaves and gravel, which must be initially screened by workers.

4. Powder grinding: The raw materials of hot spring flowers are placed into a grinder to grind to a particle size which is less than 200 mesh. Inspection: The powder must pass the Ministry of Health and Welfare's “List of Microorganisms Limits in Cosmetic Products” and meet standards such as sulfur content of 45% or more and particle size of less than 200 mesh.

“HotSpring Flower Soap” Cold Production Method

The HotSpring Flower Soap is made using a cold method. First, oil and lye are mixed and stirred, with a low temperature at about 35 °C maintained, before an appropriate proportion of hot spring powder is added. The stirring process does not need to be heated. After the soap base is thick enough, pour it into the mold while maintaining a temperature of 35-40 °C while it sits left for 24 hours. Demolding then occurs when the soap is left to sit for another day. After, the craftsmen will cut and repair the soap by hand, before stamping the soap with the seal. It is now placed in a space with good ventilation and stable temperature and humidity. After about 4 to 6 weeks, the handmade soap is finally ready. At present, the best proportion is to use 5 grams of hot spring powder in 100 grams of handmade soap, which emits a strong sulfur smell.